“More precise, More efficient”—Han’s Laser Launched Multi-axis Ultra-fast Micro-machining Equipment

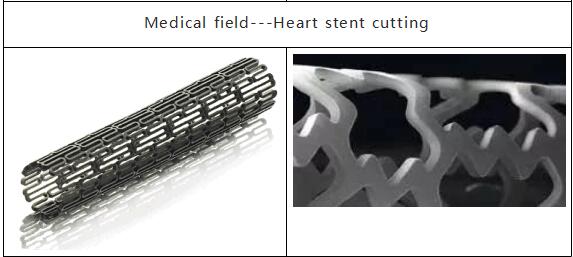

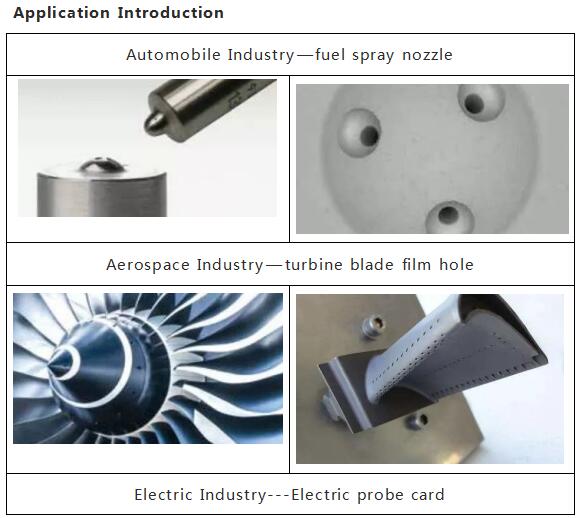

With the rapid development of precision processing technology, whether in civilian, industrial, medical or aerospace processing field, the development trend is toward miniaturization, high precision and high quality. Most traditional processing ways have been unable to meet these high precision requirements anymore. With the advantages of high-precision, high-efficiency, low-cost, high material availability, laser processing technology has become the main processing way of high-precision micro-hole processing

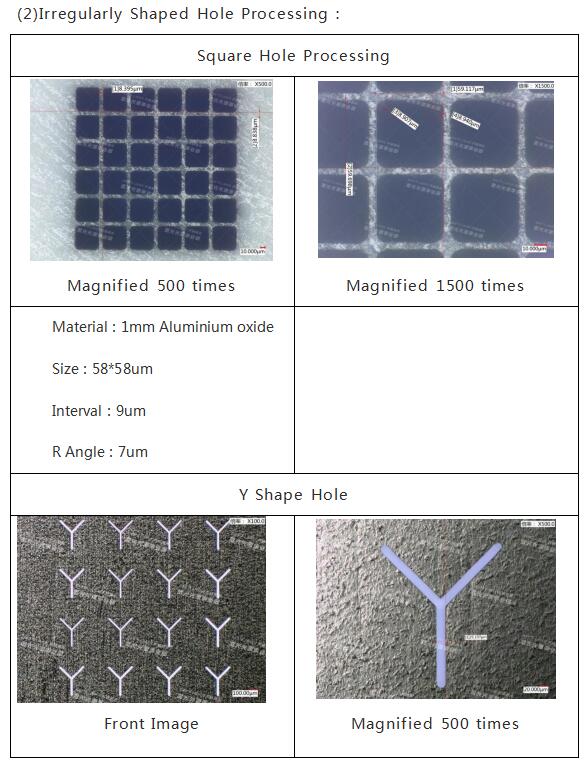

After many years of hard technology research, Han’s Laser finally broke the technical barriers, and launched the "multi-axis ultra-fast micro-machining equipment" ,HN-GY-PS60, which can not only realize X, Y, Z motion control in three directions, but also real-time Controls the rotation of the laser and changes of processing tilt angle. By setting different combination of processing parameters, users can realize various irregular drilling and cutting of holes such as cylindrical holes, positive tapered holes, negative tapered holes and square holes.

Machine Introduction

Features:

1. By setting multi-dimensional parameters in control software, to form the machining path, and output any irregular shape and any taper drilling.

2. Realize the optical quality of the processed inner wall Ra<0.1μm.

3. Equipped with coaxial high-pressure air blowing device and annular dross suction device to facilitate dross discharge.

4. High precision linear motion platform with repeatability of ±0.002 mm.

5. Optional coaxial image observation, real-time monitoring module of power

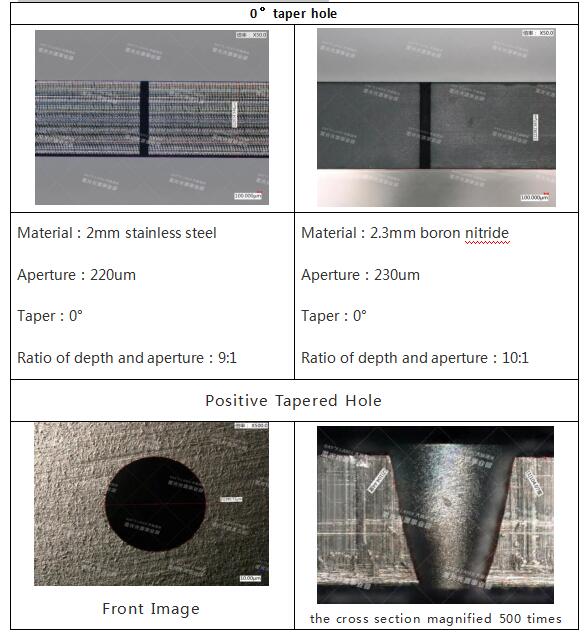

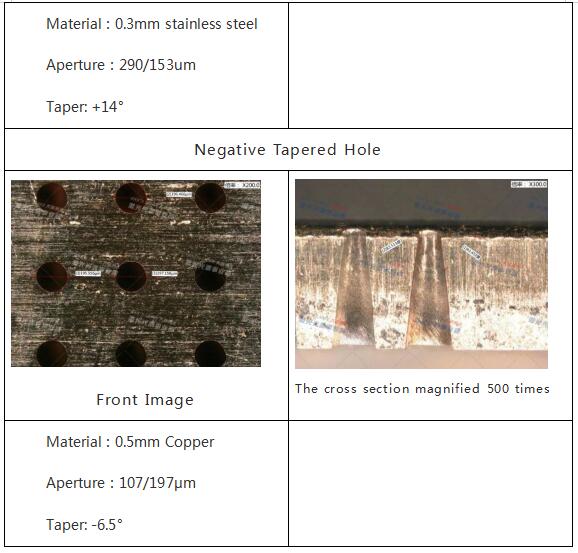

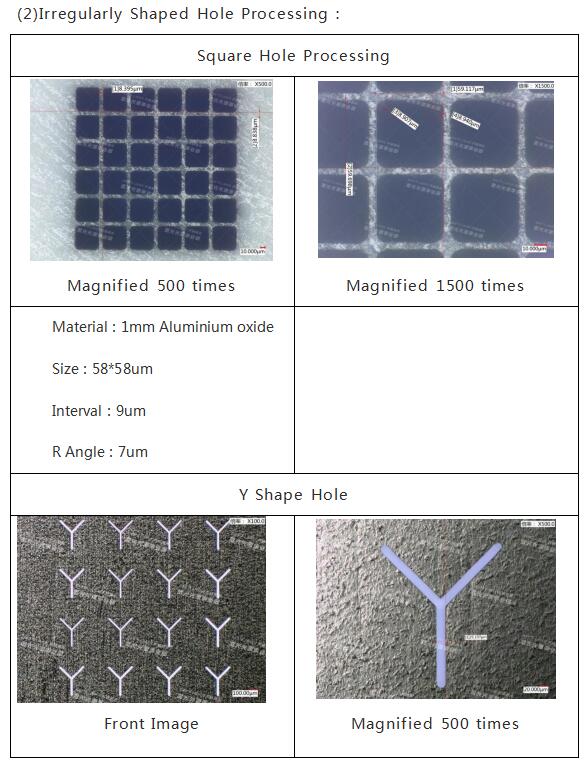

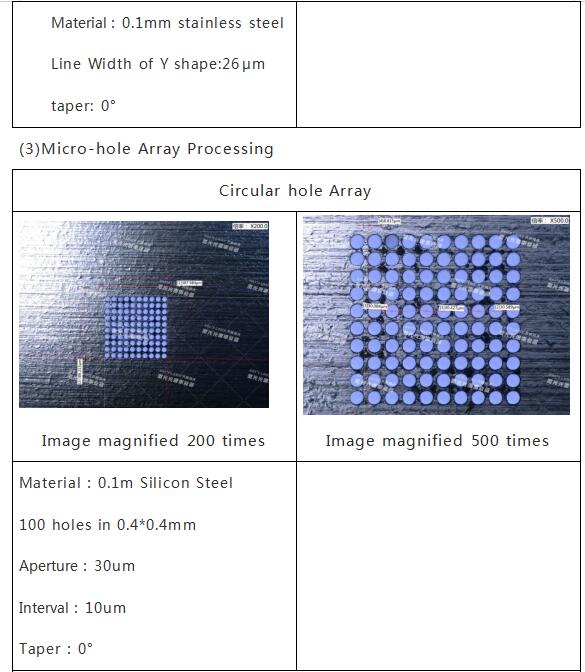

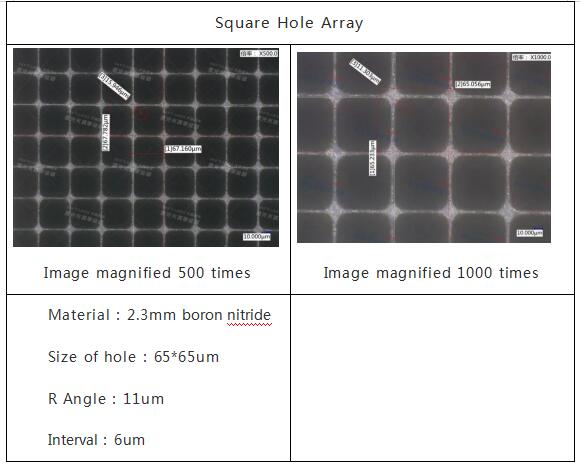

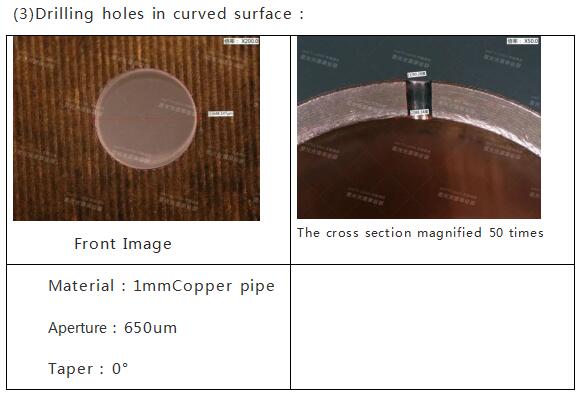

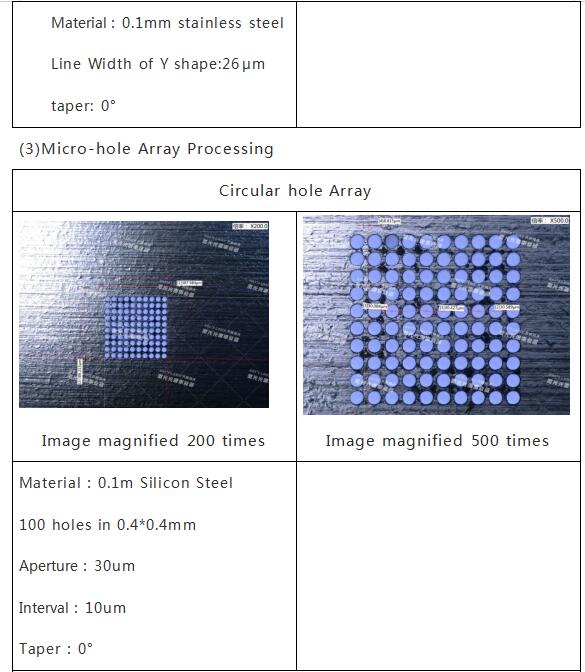

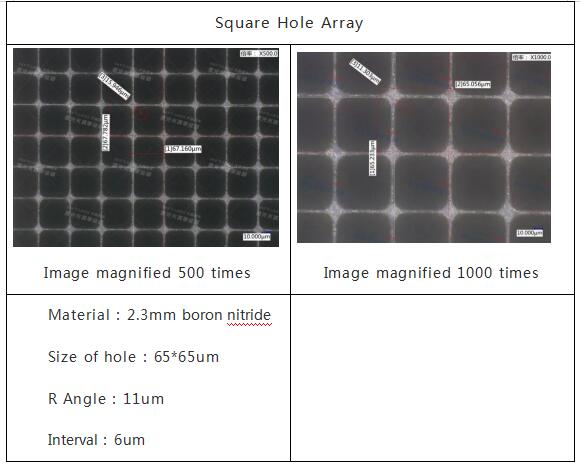

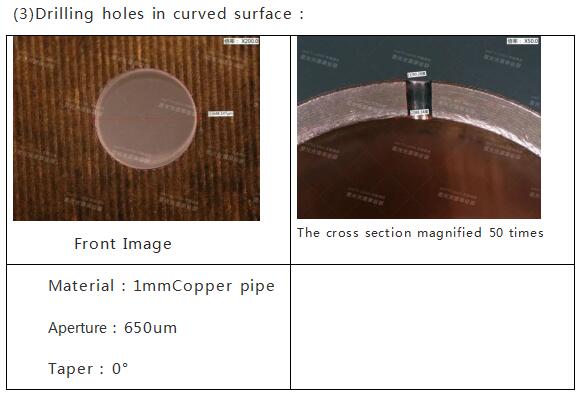

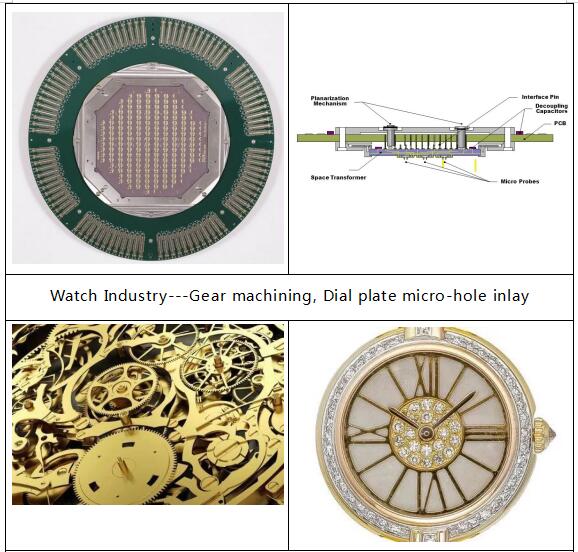

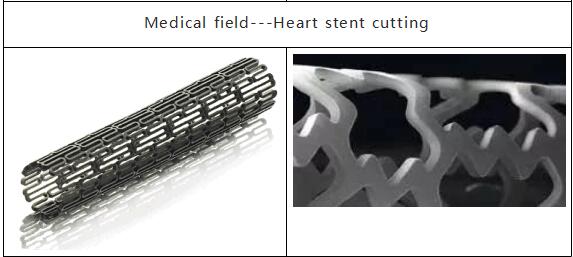

Samples Pictures:

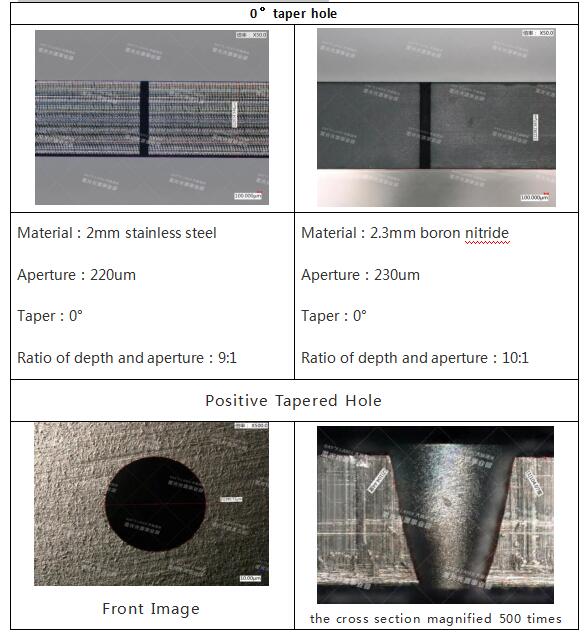

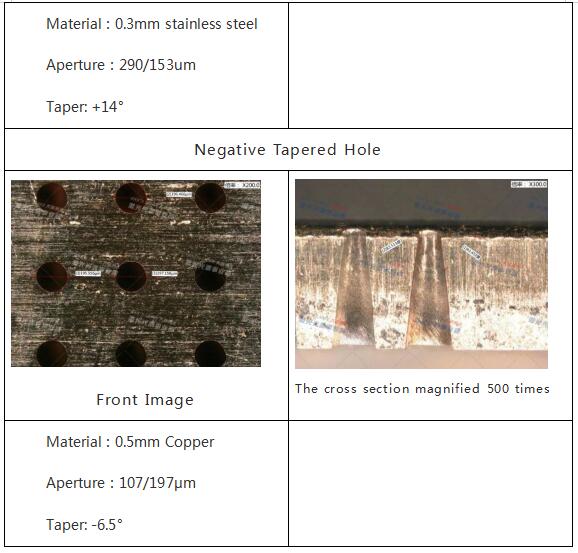

(1) Different taper hole processing:

After many years of hard technology research, Han’s Laser finally broke the technical barriers, and launched the "multi-axis ultra-fast micro-machining equipment" ,HN-GY-PS60, which can not only realize X, Y, Z motion control in three directions, but also real-time Controls the rotation of the laser and changes of processing tilt angle. By setting different combination of processing parameters, users can realize various irregular drilling and cutting of holes such as cylindrical holes, positive tapered holes, negative tapered holes and square holes.

Machine Introduction

Features:

1. By setting multi-dimensional parameters in control software, to form the machining path, and output any irregular shape and any taper drilling.

2. Realize the optical quality of the processed inner wall Ra<0.1μm.

3. Equipped with coaxial high-pressure air blowing device and annular dross suction device to facilitate dross discharge.

4. High precision linear motion platform with repeatability of ±0.002 mm.

5. Optional coaxial image observation, real-time monitoring module of power

Samples Pictures:

(1) Different taper hole processing: